I was just chatting with Zak Homuth, CEO and CoFounder at Upverter.com. It seems that the little rascals at Upverter have just launched something they call the Upverter Parts Concierge, which is best visualized as a virtual assistant for engineers.

So what is Upverter Parts Concierge and what does it offer. Well, suppose you are creating a design and you realize that you are lacking the schematic symbol and/or PCB layout footprint for one or more components. What are you going to do?

If you work for a big company, you probably have to put in an entreaty to the library team and then sit back and wait for them to deign to notice your existence and/or request. By comparison, if you work for a smaller company, you may be obliged to stop working on your design (the fun part) and get sidetracked creating these symbols and footprints (boring).

The alternative is the Upverter Parts Concierge service. Now, this can take a bit of time to wrap one's brain around, so let me take a stab at presenting a brief and simple (or cheap and cheerful) overview.

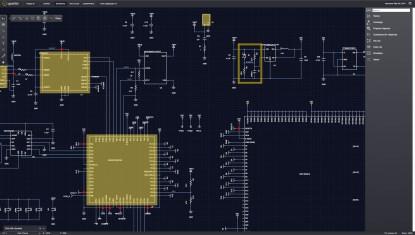

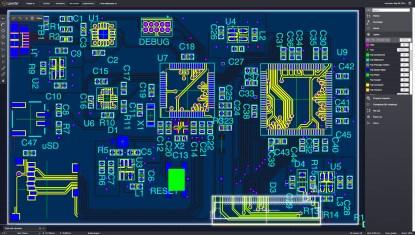

The folks at Upverter have created a suite of cloud-based EDA tools. They have things like simulators and suchlike, but at the heart of the suite we find their schematic capture and board layout applications.

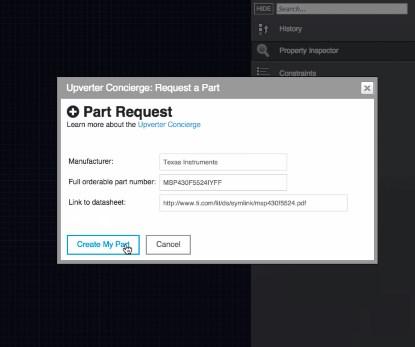

If, during the course of your design, you find you are lacking a specific part in the form of a schematic symbol and/or layout footprint, you can simply access the Upverter Concierge to request this part to be created.

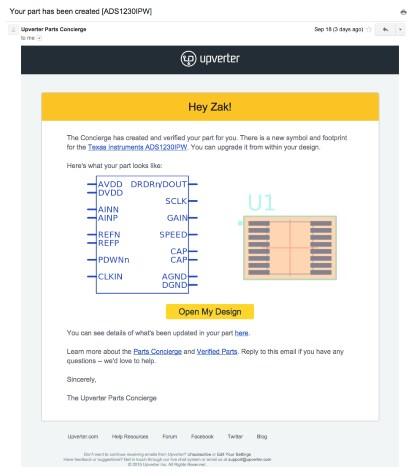

A crack team of Upverter engineers now leap into action to create and verify the component, at which time you will be notified that the little scamp is available for you to use.

How long does all of this take? Zak says that for a really simple part, if you're lucky, on a good day, with a tail-wind, you might be looking at 5 minutes; a more typical time is 30 minutes; a difficult part might take a few hours; and that their absolutely worse-case thus far has been 24 hours. Well, you can color me impressed.

But wait! Perhaps a more pertinent question is how much does this cost? Well, a starter account with Upverter is free and you are gifted with 20 free parts requests when you sign up. Of particular interest to me is that the folks at Upverter have converters, so you can request parts to be created and verified for use with your existing toolset and workflow.

Meanwhile, a professional Upverter account costs $100 a month. This paid account comes with 20 free part requests per month; after that they charge $25 per part request, which I think is exceptionally reasonable when I compare it to the value of my time, which I would rather spend doing something fun and interesting (as opposed to creating symbols and footprints -- call me "old-fashioned" if you will).

To be honest, I'd never actually heard the "back story" to Upverter. Furthermore, while chatting with Zak, I found his description of the evolution of the Upverter Parts Concierge service to be extremely interesting, so I asked him to explain how this all came about, so what follows is in Zak's words...

The origin of Upverter

We started Upverter in the summer of 2010 with the mission to build fully-cloud-based PCB design tools. We believed at the time that collaboration was such a powerful lever for knowledge that it would completely reshape the market; that Github-style “forking” and "reusing" would become the new normal; and that -- with the outsourcing culture in electrical engineering -- Google Docs-style collaborative editing and centralization would replace file and email-based workflows.

For most of the past five years we’ve been working to make this tool a reality. We’ve built fully-cloud, fully-featured schematic capture, PCB layout, parts library creation and management, constraints management, BOM management, and system design tools.

Our main revenue early on came from helping engineers to manufacturer their designs. Later, we started charging for our premium accounts. We still make most of our money from the design tools, but we also now charge for services like the parts concierge, verification, design review, and layout services -- all built on top of the Upverter design tools.

The origin of parts

Almost 99% of users that have ever designed a board in Upverter still use it today. For a long time, though, we had a really hard time convincing engineers to spend the four to six hours that it takes to learn Upverter. Most users would signup, poke around a little bit, and then leave, never actually experiencing how or why Upverter is better. We call this “activation.”

Activation became our single biggest business problem. If we could find a way to get engineers to try Upverter, then we would grow and thrive; if we couldn’t, then we’d fail and fall by the wayside.

Thus, we were looking for a way to make Upverter feel very different from any other EDA tool; we were looking for what we call instant gratification -- that thing the user experiences in the first few moments on Upverter that makes them say “Ahh... I get it”; the thing that shows them how and why Upverter is different while also making their lives as engineers significantly better.

Around the same time, we also realized that creating, verifying, and managing parts and libraries was an enormous problem. We’d known this implicitly all along, but we’d never thought of it as a problem that could be solved. We thought this was just one of those things it means to be an EE. It sucked, but you had to copy parts out of datasheets, you had to do it my hand, and you had to do a good job, otherwise things weren't going to work when you progressed to manufacturing.

While we were doing interviews with our customers, this topic just kept coming up. In addition to mentioning the cost of EDA tools, and how manufacturing seems to be getting harder, almost everyone expressed frustration about parts. This included a lot of fear and paranoia; the hardest thing about switching EDA tools seemed to be losing one of the assets everyone valued most -- their part library.

We also looked at our stats; the very first thing everyone did when they tried Upverter was to search for a part. If they found the part, there was a pretty good chance they’d stick around; if they didn’t find the part, there was a pretty good chance they’d leave.

All of this got us thinking. Maybe parts wasn’t impossible. We obviously couldn’t just go out there and build every part in the world, but maybe we could build any part a user required quickly enough that it would be like it was there in the first place.

How it works

Our theory was that we could establish a real-time on-demand service where users asked for parts, these parts got added into a queue, and component engineers working at Upverter could work to rapidly clear that queue -- creating the parts in the background for users as they got requested.

The pilot program

So we built a pilot version. We deployed this secretly into Upverter and we watched what happened. Almost immediately we got slammed with 600 part requests. At that time, it took us an average of 54 minutes to create a part, so this was a really big problem. We simply couldn’t handle this level of demand, so we had to pause the service (we satisfied all of the original parts requests, of course) and go back to the drawing board. Engineers obviously valued this service, but it was just too hard and too expensive for us to support in its original incarnation.

The science "under the hood"

We spent the next couple months building and testing a suite of machine intelligence and software automation tools to make our component engineers faster and better. We experimented with interface improvements, datasheet scraping, footprint generators, symbol generators, 3D model footprint extraction, etc. At the end of all this R&D, we were able to reduce our part creation time down to an average of 7.5 minutes per part.

Furthermore, it's important to note that we do this without any outsourcing; experienced electrical engineers working in North America perform all of the creation and verification. It still takes us about 15 minutes to verify a part and, thus far, we haven’t done too much to make this part of the process faster -- we like the fact that a human is checking the part before we give it our final stamp of approval.

Ready to launch

Once we had our new tools and flow established, we turned the concierge back on a few weeks ago and things have been going very well. We currently have a team of seven engineers that take rotating shifts creating and verifying the parts. Together, they process over a hundred parts a day with an incredibly low error rate (I think we're aware of only one minor error in the thousands and thousands of parts we’ve created and verified thus far).

Interoperability

We’ve also started offer this as a service outside of Upverter. You can request parts to be created or verified and still continue using your existing toolset and workflow. We have created whole libraries and verified large existing libraries. We interoperate with all the major tools, and our turn-around time is within the same day (usually in just a few hours).

Pricing

Verified parts and the concierge come built into Upverter. We give every user 20 free part requests and the ability to create two private designs when they signup. Meanwhile, every paid plan comes with 20 free parts requests per month (after that we charge $25 per part request).

We’re currently working on standard enterprise and third-party pricing models; for the moment, however, we’re asking people to just contact us.

Quotes

Here are a couple of quotes I'd like to share:

- “It’s seamless. Very easy and hard to believe.” - Nate Fisher, Electrical Design Engineer, PCH Lime Lab.

- “Knowing that a part is approved by the concierge provides peace of mind and allows me to get a product out the door to our customers sooner.” - Logan Poe, Chief Hardware Designer, LightEmUp Band.

- “Parts Concierge seems magical and is fantastically useful!” - Oren Weiss, Hardware Engineer, Intel.

About Upverter

The way engineers design hardware needs an update. Upverter builds tools that are setting hardware design back on track and bolstering it with new and innovative technology. Upverter is best known as the developers of the first fullycloud-based, fullycollaborative electronics design system that helps tens of thousands of engineers to build better hardware products faster than ever before.

/5

/5

文章评论(0条评论)

登录后参与讨论