Over time, I have developed a horror of replaceable, single-use batteries. I'm not particularly a greenie, but it just seems to be an incredible waste when rechargeable batteries are available. The LED torches you get these days are much more efficient battery users, but when I saw these LED torches in a local store for only $5 and bought a few, I still wanted to make them rechargeable, off a 12 V supply.

They use the square 6 V lantern batteries with the springs on the top. You do see rechargeable ones, but they're hellishly expensive.

I'd picked up a box of these boards that someone was chucking out. Each board had five rectangular 400 mAH NiCd cells, a PCB, and some components. I'd removed and used some of the batteries in other projects. Those batteries were made by Sanyo and if there's one thing Sanyo do well, it is make rechargeable batteries. But could I use them for this project?

I took apart an old lantern battery to see what I could do with it. It had four compartments with one large zinc-carbon cell in each, each of which I removed. But if I removed two of the dividers, my Sanyo NiCds just fitted lengthways into the larger compartment. By forming them into 6 V packs consisting of three cells on top of each other and two vertically, I found I could fit 10 of my packs into a modified empty lantern cell case. That's 4 AH of battery, albeit in small chunks. The remaining space in the top of the battery pack was minimal. But I love challenges like this...

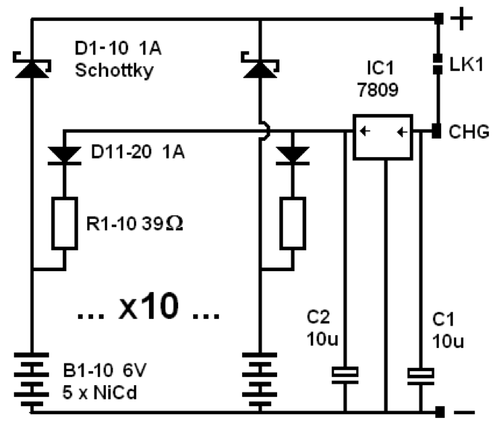

I decided I wanted the sharing components and a charging circuit inside the battery. Sharing is easy. Each battery pack had the negative terminals tied together, and a Schottky diode (to minimise voltage drop) from its positive terminal onto the common positive terminal. For charging, I worked on the principle that when it is charged, a NiCd will approach 1.5 V per cell. I used a 7809 regulator to give a 9 V supply, with a standard diode (0.6 V drop) and a 33-Ω resistor in series to each battery pack. If the cell is at 1.5 V, the charge current will be (9 – 0.6 – (5 x 1.5)) / 33 = 0.9 V / 33 Ω = 27 mA, well below the 1/10 C – 40 mA in this case—that is safe for trickle-charging a NiCd. If the battery is discharged, say at 6 V, the current would be larger, around 72 mA. The result was a fast initial charge tapering off to a low rate, which is safe if you leave it on for days. Since the battery packs had the Schottky diodes going to the main positive terminal, I thought I could use the positive terminal for charging as well. This was my circuit:

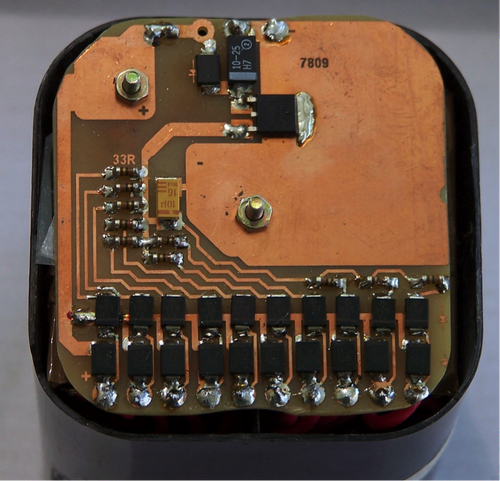

The small space left inside the top of the battery meant I'd have to use surface-mount components, something I'd never done before. More challenge. I got some SMD diodes, resistors, and regulators really cheap off Element 14's bargain pages and designed a PCB around them. The battery springs were mounted to the case with rivets. I drilled these out and used small bolts and nuts to connect them to—and securely mount—my PCB. I had a fair bit of PCB real estate available due to the small size of my SMD components, so I used some for a heat sink for my regulator.

Everything just fit inside the battery case. I used a couple of layers of plastic to separate the batteries from the PCB. The components were on the other side from the batteries but the bolt heads protruded through. I did not want any shorts.

The torches worked well. I get a good few hours of light out of them on a fully charged battery. I did find a couple of minor problems:

* The battery is not short-circuit proof. I did inadvertently short one once. It blew a PCB track under a diode, but no components. I have since modified the PCB to have a constriction in the main track away from any diodes, so if it does blow it will blow there, where it's at least accessible.

* The batteries showed a far higher than expected self-discharge rate. Although there are diodes that stop the individual batteries discharging into the regulator, I failed to notice that the main common positive line goes, through a diode, to the regulator input. The 7809 regulator will not work with 6 V going into it, but it will draw a quiescent current. I kind of like it when this happens. It shows me that I'm not as smart as I think I am...

* Fortunately I included a link on the board (LK1 In the schematic) so that the 12 V charging source can be connected separately. I opened the link and took a wire outside the battery. I could take this to a socket, but will probably put a couple of contacts on the body of the torches and build a charging bay for them.

* When the batteries are very flat, the regulator tends not to give the full 9 V out. I found this was due to my regulators being the M type, which limit at 500 ma, though this wasn't stated when I bought them. It's not a problem, since it only limits the charge current delivered to a flat battery pack and as it charges the regulator very soon starts regulating correctly again. These batteries were not rated for fast charging, so this limit is probably a good thing!

All in all... Cost: Less than $10 per torch. Running cost: almost nothing. Satisfaction: Priceless!

Don Tavidash submitted this article as part of Frankenstein's Fix, a design contest hosted by EE Times (US).

/4

/4

文章评论(0条评论)

登录后参与讨论