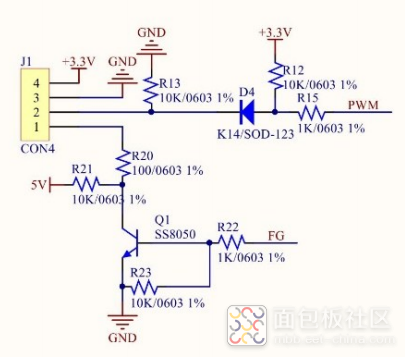

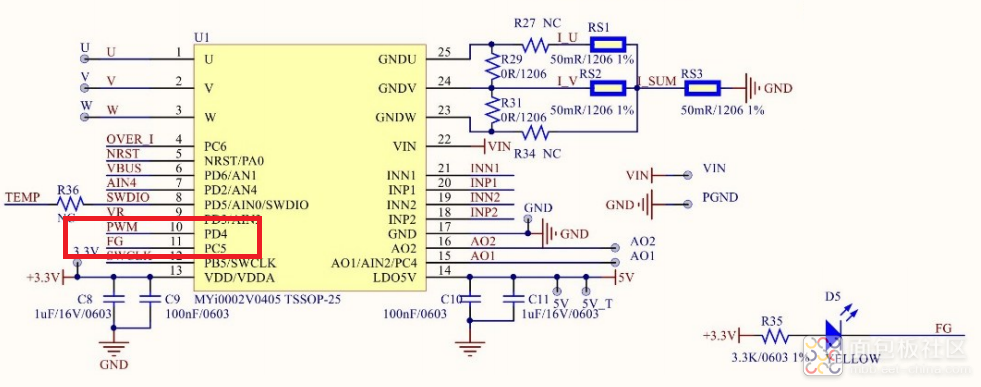

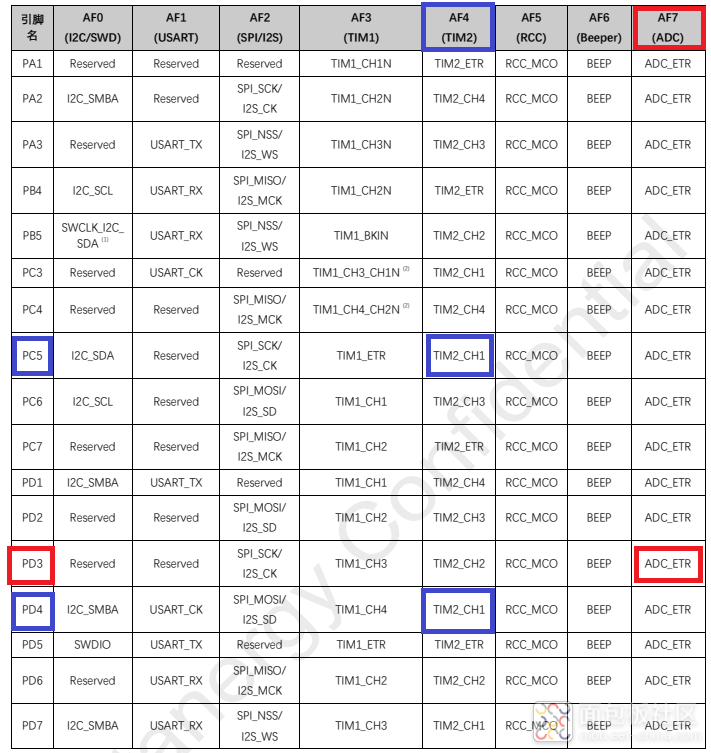

这两个引脚最终可以通过电路连接到PD4和PC5上,而根据单片机的GPIO复用,

在AF4方式下,PD4和PC5都可以作为定时器2的通道1输出。为了后面使用PWM驱动马达的测试以及作为显示提示,使用PC5显示当前PWM的占空比状况,我想同时使用PD4和PC5作为定时器2的PWM输出通道。为此在程序中按照下面的方式初始化GPIO:

/*IO初始化*/

void GPIO_Configuration(void) {

//初始化模拟IO PC4

GPIO_InitTypeDef GPIO_InitStructure;

// PD4 : 定时器控制PWM输出, AF4 模式下PD4为输出通道

GPIO_InitStructure.GPIO_Pin = GPIO_Pin_4;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_AF;

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_10MHz;

GPIO_InitStructure.GPIO_OType = GPIO_OType_PP;

GPIO_InitStructure.GPIO_PuPd = GPIO_PuPd_NOPULL ;

// PD4 = TIM2 Channel 1*/

GPIO_Init(GPIOD, &GPIO_InitStructure);

GPIO_PinAFConfig(GPIOD, GPIO_PinSource4, GPIO_AF_4);

// PC5 : LED : 定时器控制PWM输出, AF4 模式下PC5为输出通道

GPIO_InitStructure.GPIO_Pin = GPIO_Pin_5;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_AF;

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_10MHz;

GPIO_InitStructure.GPIO_OType = GPIO_OType_PP;

GPIO_InitStructure.GPIO_PuPd = GPIO_PuPd_NOPULL ;

// PC5 = TIM2 Channel 1*/

GPIO_Init(GPIOC, &GPIO_InitStructure);

GPIO_PinAFConfig(GPIOC, GPIO_PinSource5, GPIO_AF_4);

}

复制代码按照下面的方式设置定时器:

void TIM_Config(void) {

TIM_TimeBaseInitTypeDef TIM_TimeBaseStructure;

TIM_OCInitTypeDef TIM_OCInitStructure;

TimerPeriod = (SystemCoreClock / 10000) - 1; //配置输出10KHZPWM

/* Compute CCR1 value to generate a duty cycle at 50% for channel 1 */

Channel1Pulse = (uint16_t)(((uint32_t) 1 * (TimerPeriod - 1)) / 10);

/* Time Base configuration */

TIM_TimeBaseStructure.TIM_Prescaler = 0;

TIM_TimeBaseStructure.TIM_CounterMode = TIM_CounterMode_Up;

TIM_TimeBaseStructure.TIM_Period = TimerPeriod;

TIM_TimeBaseStructure.TIM_ClockDivision = 0;

TIM_TimeBaseStructure.TIM_RepetitionCounter = 0;

TIM_TimeBaseInit(TIM2, &TIM_TimeBaseStructure);

/* Channel 1 Configuration in PWM mode */

TIM_OCInitStructure.TIM_OCMode = TIM_OCMode_PWM2;

TIM_OCInitStructure.TIM_OutputState = TIM_OutputState_Enable;

TIM_OCInitStructure.TIM_Pulse = Channel1Pulse;

TIM_OCInitStructure.TIM_OCPolarity = TIM_OCPolarity_Low;

TIM_OC1Init(TIM2, &TIM_OCInitStructure);

//TIM_SelectOnePulseMode(TIM2, TIM_OPMode_Single);

/* TIM2 counter enable */

TIM_Cmd(TIM2, ENABLE);

}

复制代码为了方便查看占空比是否发生了变化,在主程序中循环调整占空比从10%到90%。

int main(void) {

uint32_t zkb = 0;

uint32_t mode = 0;

RCC_Configuration();

GPIO_Configuration();

ADC_Configuration();

TIM_Config();

softWareDelay();

while (1) {

softWareDelay();

// 改变占空比:

if (mode == 0) {

zkb=(zkb+1)%10;

if (zkb == 9) {

mode = 1;

}

} else {

zkb=(zkb-1)%10;

if (zkb == 0) {

mode = 0;

}

}

TIM2->CCR1 = (uint16_t)((zkb * (TimerPeriod - 1)) / 10);

}

}

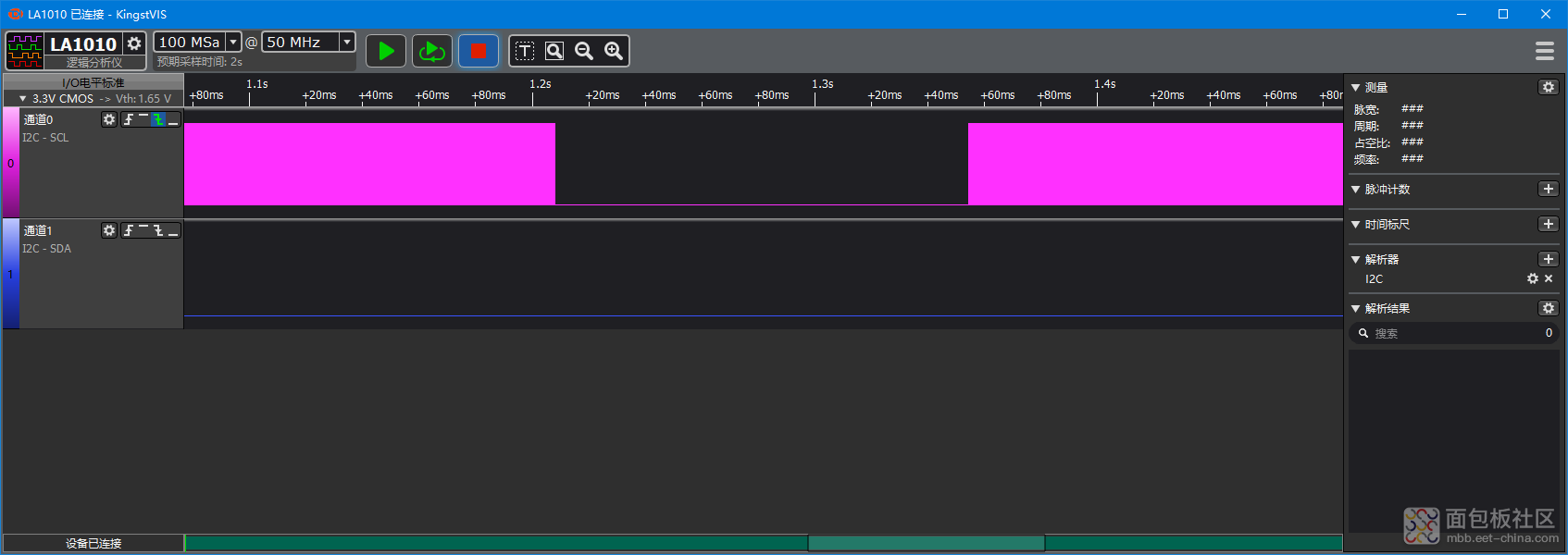

复制代码测试结果:

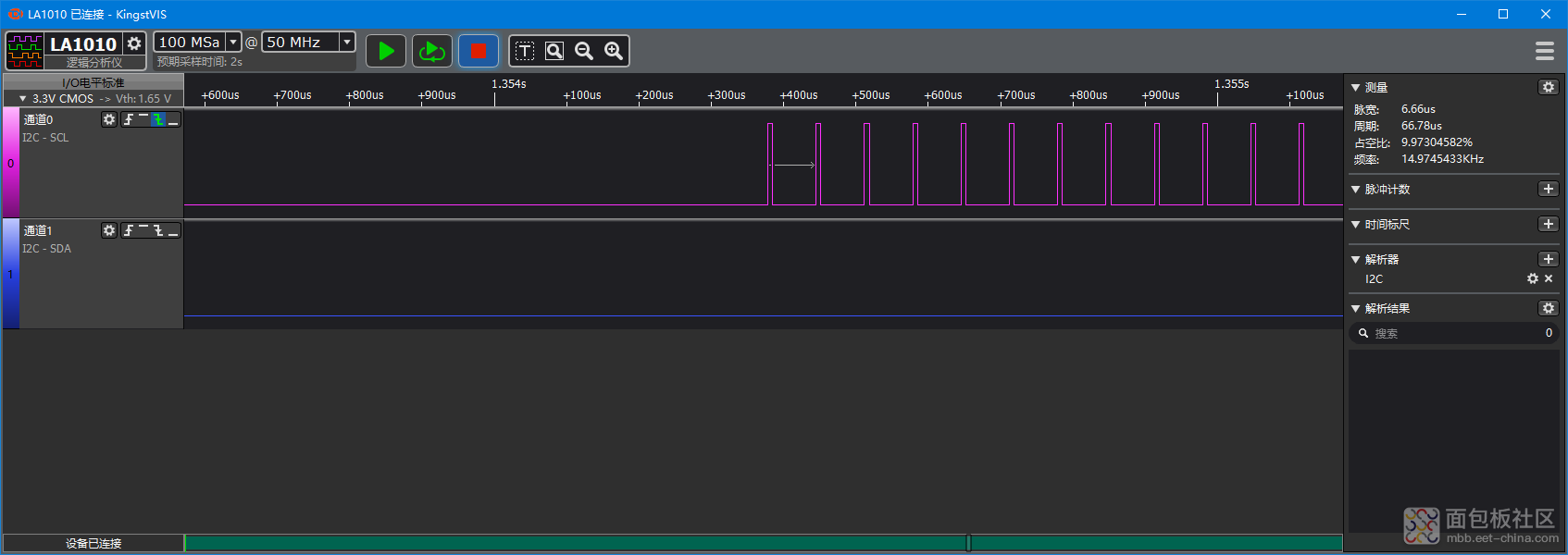

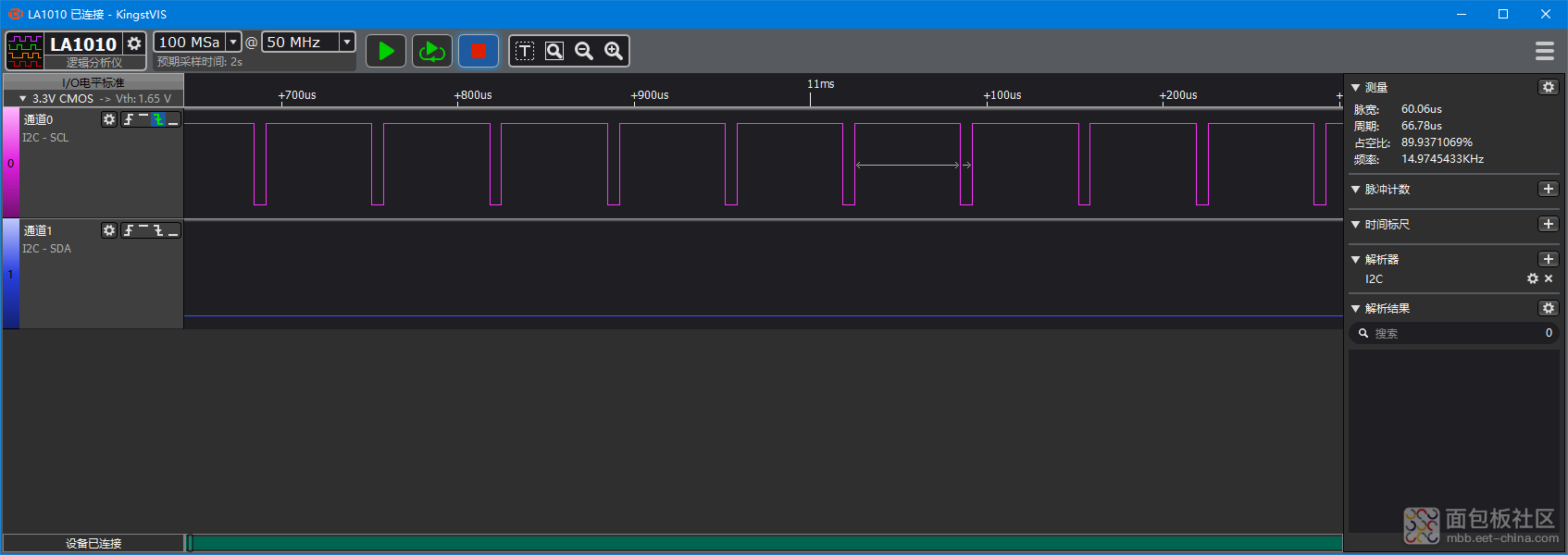

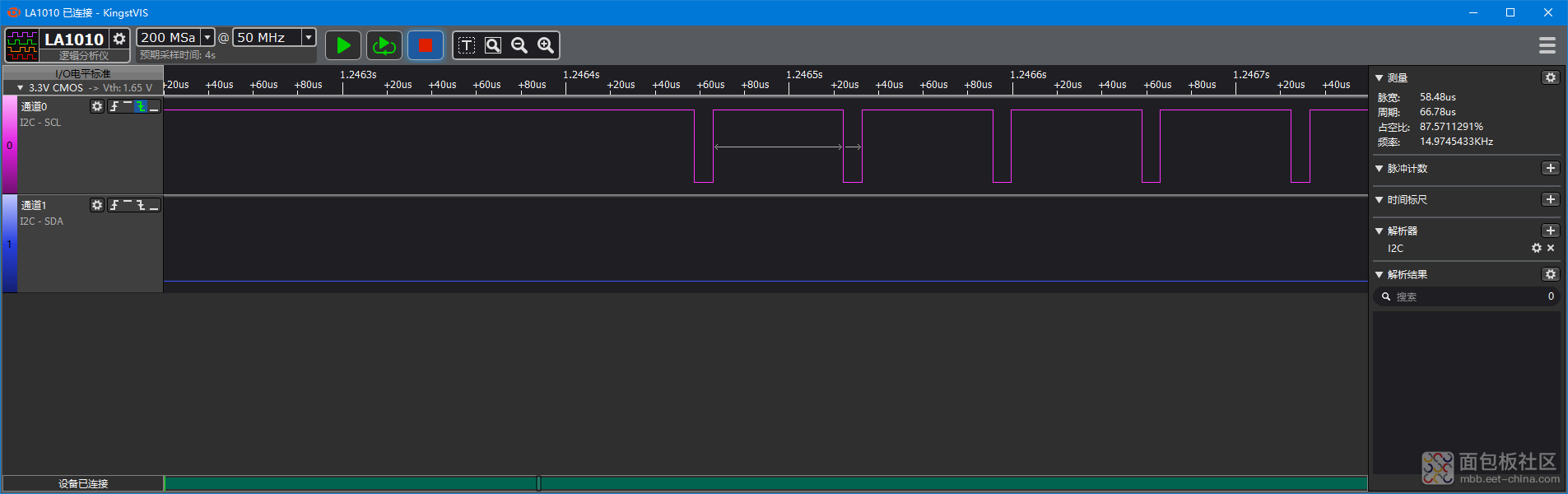

用逻辑分析仪捕获到的PWM输出针脚的PWM数据:

最小的占空比处:

为10%不到,最大的占空比处:

不到90%,与程序代码基本上是匹配的。

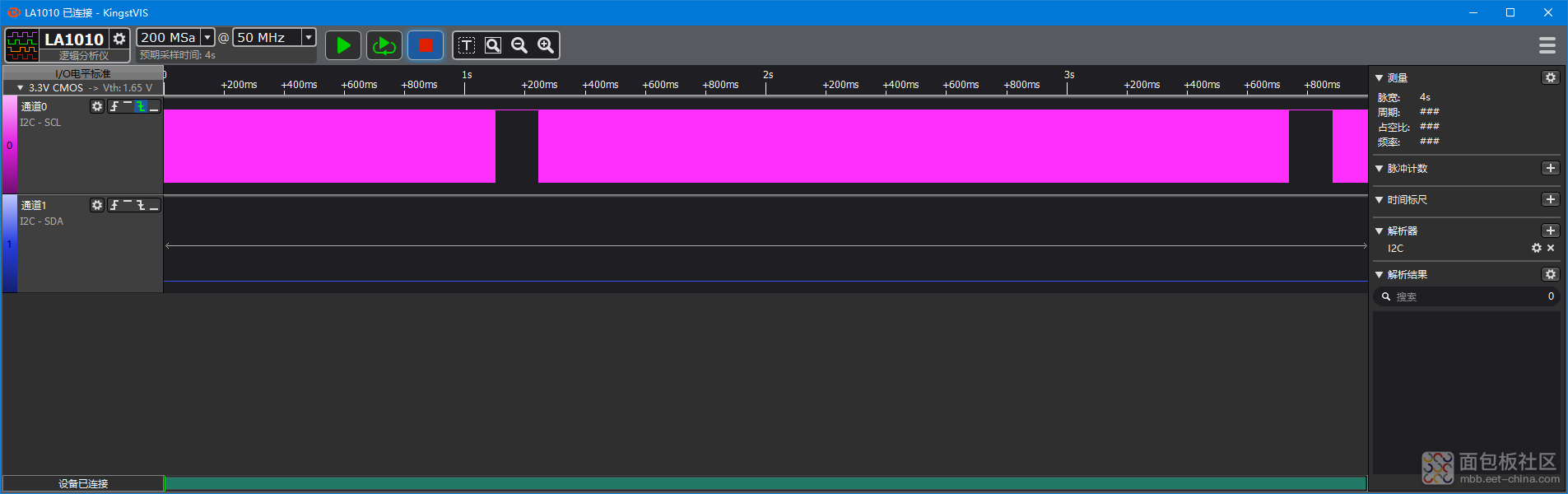

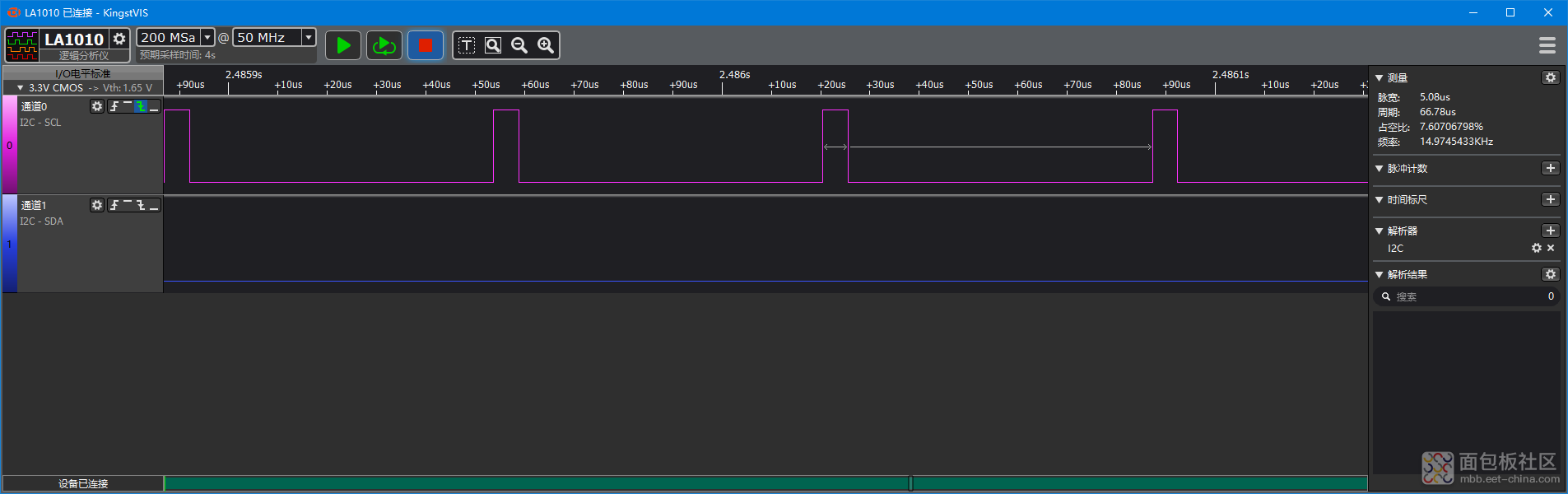

用逻辑分析仪捕获到的FG输出针脚的PWM数据:

最小的占空比处:

为10%不到,最大的占空比处:

不到90%,与程序代码基本上也是匹配的。

本次测试证明,是可以同时使定时器的PWM输出通道输出给不同的GPIO口的。

/4

/4